Some Of Laser Cutting Equipment

Wiki Article

On the subject of fashionable producing, the precision and performance of laser reducing engineering are really game-switching. Laser reducing machines have revolutionized industries by furnishing a means of chopping elements with unparalleled precision. In case you’ve ever marveled for the intricate models on metal or puzzled how elaborate designs are created so seamlessly, it’s often the operate of the industrial laser reducing equipment.

Allow’s get started with the fundamentals: a laser cutter is a Instrument that utilizes a laser beam to chop supplies. This beam is incredibly focused and generates superior temperatures to melt or vaporize the fabric, earning exact cuts. Unlike classic approaches, which could use mechanical blades, a laser cutter offers a degree of accuracy that is sort of unmatched. Think about wanting to carve a fragile sample having a hammer—Obviously, a laser cutter is a whole lot much more refined!

Industrial laser slicing will take this technological innovation to the subsequent degree, offering alternatives for giant-scale operations. These machines are created to manage significant elements and high generation volumes, making sure that even essentially the most demanding initiatives are concluded with superior efficiency. Think of it because the difference between utilizing a precision knife for sensitive paper crafts and a powerful noticed for reducing by way of thick wood.

6 Simple Techniques For Cnc Laser Cutting

On the globe of CNC laser slicing, the “CNC” stands for Personal computer Numerical Handle. This engineering allows for automatic and remarkably precise cuts by following electronic models. In case you’ve ever used a pc to draw and after that found that drawing arrive at existence, CNC laser chopping will work in an identical way, translating digital models into physical cuts. It’s like having a Digital designer With all the precision of the laser.

On the globe of CNC laser slicing, the “CNC” stands for Personal computer Numerical Handle. This engineering allows for automatic and remarkably precise cuts by following electronic models. In case you’ve ever used a pc to draw and after that found that drawing arrive at existence, CNC laser chopping will work in an identical way, translating digital models into physical cuts. It’s like having a Digital designer With all the precision of the laser.Top Guidelines Of Sheet Metal Laser Cutter

Precision laser chopping is not pretty much building cuts; it’s about generating them appropriate each time. The laser may be adjusted to achieve different depths and widths, making sure that each Lower is exactly where by it really should be. This is certainly vital for programs where even a slight deviation could lead on to important concerns. Think of it for a surgeon’s scalpel, the place precision is not just vital but Certainly vital.

Precision laser chopping is not pretty much building cuts; it’s about generating them appropriate each time. The laser may be adjusted to achieve different depths and widths, making sure that each Lower is exactly where by it really should be. This is certainly vital for programs where even a slight deviation could lead on to important concerns. Think of it for a surgeon’s scalpel, the place precision is not just vital but Certainly vital.Laser chopping products comes in many kinds, Every personalized to certain needs. Irrespective of whether You'll need a small desktop design for hobby assignments or a massive industrial device for manufacturing unit use, there’s a laser reducing Alternative in existence for you personally. These devices differ in energy, pace, and capabilities, so it’s essential to choose the appropriate one on your particular application.

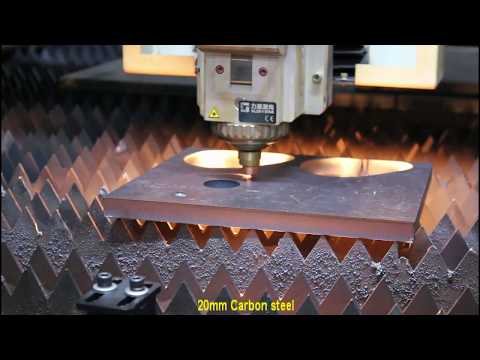

Sheet metallic laser cutters can be a Particular classification of laser cutting machines made especially for cutting steel sheets. These are widely Utilized in industries starting from automotive to aerospace because of their power to deal with steel with precision and pace. Photo a sheet of metallic similar to a blank canvas, and also the laser cutter since the artist who results in elaborate and delightful patterns with amazing accuracy.

Laser slicing products and services are another essential aspect of this engineering. Not Absolutely everyone desires to take a position in their own individual laser cutting equipment, particularly when they only need occasional cuts or deficiency the House for such equipment. Many companies offer laser chopping products and services in which you can send out your models and also have them Minimize with substantial read this precision. It’s like outsourcing your artwork to a skilled Skilled.

Laser reducing methods combine many parts to deliver the specified outcomes. In the laser source for the reducing bed, as well as Manage computer software, each part of the process operates together to be sure a flawless Procedure. It’s a tad like a symphony orchestra, where by Every single musician has a specific job, and only by Doing work with each other do they make a harmonious effectiveness.

In terms of laser chopping technological innovation, the evolution continues to be immediate and remarkable. Initially utilised know more mainly for slicing metals, these equipment now manage a variety of supplies together with plastics, wood, and in many cases fabrics. This versatility helps make laser chopping technologies a beneficial tool in many industries. Visualize possessing a Swiss Military knife which can deal with virtually any product—This can be what present day laser chopping technology gives.

The precision of laser chopping equipment is truly exceptional. They could Slice materials to inside microns in the meant style and design, making sure that even probably the most intricate specifics are preserved. This amount Laser Cutting Machine of precision is especially precious in industries where by correct measurements are essential. Consider it because the difference between a tailor-made fit and off-the-rack clothes—the suit is just ideal each and every time.

Some Known Facts About Cnc Laser Cutting .

A further advantage of laser slicing technology is its effectiveness. Compared with standard slicing methods That may have to have multiple methods or applications, laser cutting typically completes the endeavor in one go. This not just hurries up output but additionally lowers product squander. It’s like having a large-pace educate that receives you to your vacation spot speedily and successfully with none unnecessary stops.During the context of industrial apps, the robustness of laser slicing devices is important. These equipment are crafted to endure the requires of continual Procedure, often operating 24/7 in higher-volume settings. Their durability ensures constant efficiency and reliability, which can be essential for sustaining manufacturing schedules. It’s like possessing a hefty-duty truck that reliably provides merchandise working day soon after day.

Among the outstanding aspects of laser chopping is its power to make clear and precise edges. This reduces the necessity for put up-processing, for example sanding or ending, which can be time-consuming and dear. The result is really a smooth, concluded products That usually demands minimal supplemental operate. Picture ending a craft job without any glue spills or tough edges—it’s that cleanse!